What is the difference between a silicone surfactant and a defoamer?

Exploring the Distinction: Surfactants vs. Defoamers

A surfactant is a substance that reduces the surface tension of a liquid, allowing it to spread more easily and mix with other liquids. Surfactants are used in a variety of applications, including cleaning, foaming, and emulsifying.

A defoamer is a type of surfactant that is used to prevent or break up foam. Foam is a dispersion of gas bubbles in a liquid, and it is stabilized by surfactants. Defoamers work by disrupting the surfactant film that stabilizes the foam bubbles, causing them to collapse.

The main difference between a surfactant and a defoamer is their purpose. Surfactants are used to reduce surface tension, while defoamers are used to break up foam.

Understanding Surfactants:

Surfactants, those remarkable surface-active agents, are integral to our daily lives. Their main task is to lower the surface tension between liquids or between a liquid and a solid. This property enables them to disperse, wet, emulsify, foam, and even help with cleaning processes. The molecular structure of surfactants consists of a hydrophilic (water-attracting) and a hydrophobic (water-repelling) part, which allows them to bridge the gap between two immiscible substances.

What is Surface Tension?

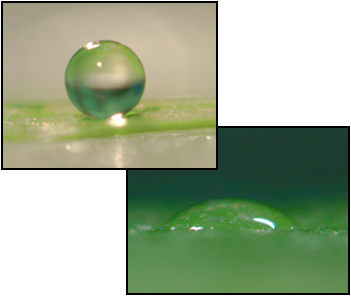

Let’s have a look at the image on the left, it makes it clearer to understand. When the surface tension is high, the water droplet struggles to spread across the leaves. However, when surface tension is lower, the droplet spreads out, creating a flatter shape and a smaller contact angle. This allows the water to easily wet the leaves, making them easier to spread.”

Applications of Surfactants:

Surfactants find their utility across various domains:

Agriculture: In pesticides, surfactants help ensure even distribution and absorption on plant surfaces.

Household Cleaning: They’re the heroes in your cleaning solutions, breaking down grease and grime to leave your surfaces sparkling clean.

Personal Care: Shampoos, body washes, and toothpaste all owe their creamy consistency and ability to mix with water to surfactants.

Oil Industry: Enhanced oil recovery involves the use of surfactants to improve the extraction process.

Understanding Defoamers:

Defoamers, as the name suggests, are compounds that prevent or suppress foam formation. Foam, although visually appealing, can hinder various processes and lead to inefficiencies. Defoamers work by destabilizing foam bubbles, causing them to collapse.

Applications of Defoamers:

Food and Beverage: In edible oils, beverages, and food processing, defoamers prevent excessive foam that could affect the quality of the end product.

Paper and Pulp: During paper production, foam can interfere with the consistency of paper sheets. Defoamers ensure a smooth production process.

Wastewater Treatment: Foam can be a nuisance in wastewater treatment facilities. Defoamers aid in preventing foam buildup in aeration tanks.

| Feature | Surfactant | Defoamer |

| Purpose: | Reduces surface tension | Breaks up foam |

| How it works: | Forms a film at the air-liquid interface | Disrupts the surfactant film that stabilizes foam bubbles |

| Applications: | Cleaning, foaming, emulsifying | Preventing or breaking up foam |

Key Differences:

While both surfactants and defoamers deal with interfaces and surface properties, they operate in distinct ways:

Function: Surfactants enhance the interaction between two substances, whereas defoamers disrupt foam formation.

Composition: Surfactants have hydrophilic and hydrophobic parts, while defoamers typically consist of oil-based compounds or silicone.

Objective: Surfactants aim to stabilize mixtures of different substances, while defoamers strive to destabilize foam structures.

Their unique characteristics and applications make them invaluable assets across multiple sectors. So, the next time you encounter a bubbly situation, remember, that Romakk Silicones got you covered. Whether in your household products or industrial processes, you’ll know whether to reach for a Romakk Silocone’s surfactant or a defoamer.